Leave your email and demand to get a copy of the factory price! now!

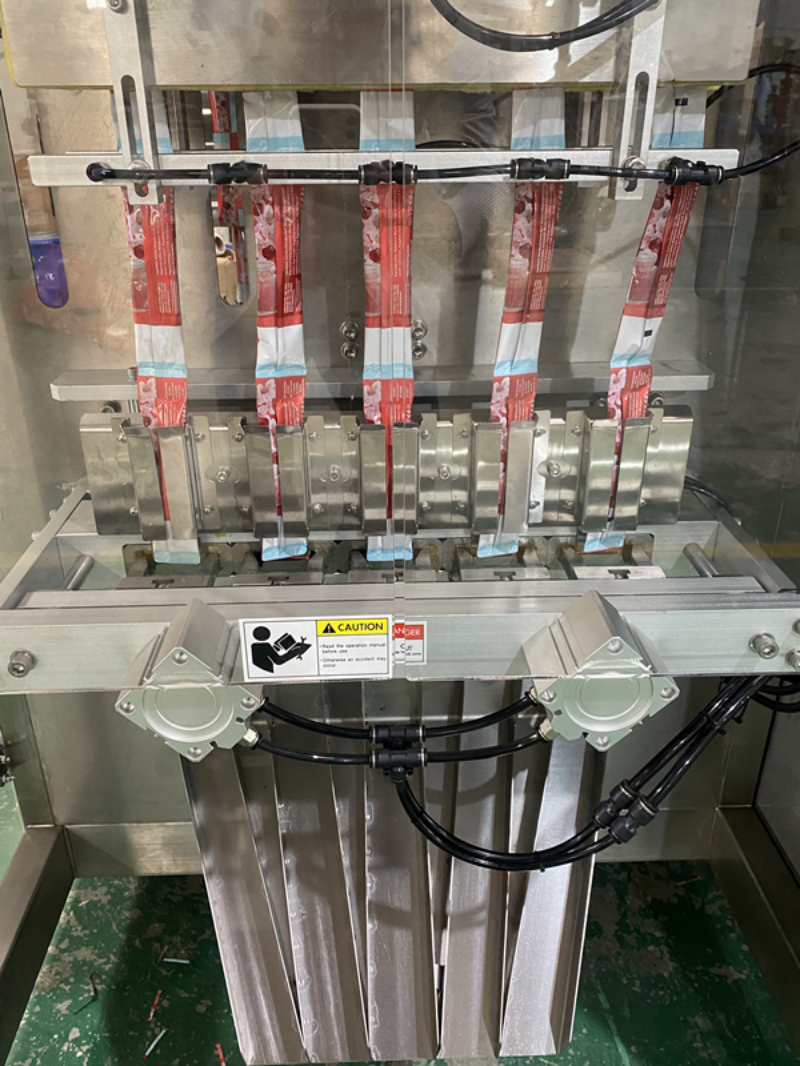

Oil Packing Machine Product Description

1. Function:

Automatically feeding, measuring volume, making bags, filling, sealing, cutting, printing the lot number and cutting easy tearing notches, finished product conveying.

2. Standard Features:

(1). Famous brand PLC control system, large touch screen, convenient to operate;

(2). Film drawing down the system by famous bland servo motor control.

(3). Auger doser is controlled by a brand servo motor, which volume is adjustable on the screen

(4). Advanced design, high precision, and fast speed;

(5). Various alarm systems to reduce waste;

(6). Photoelectric tracking system for precise bag length and position of film

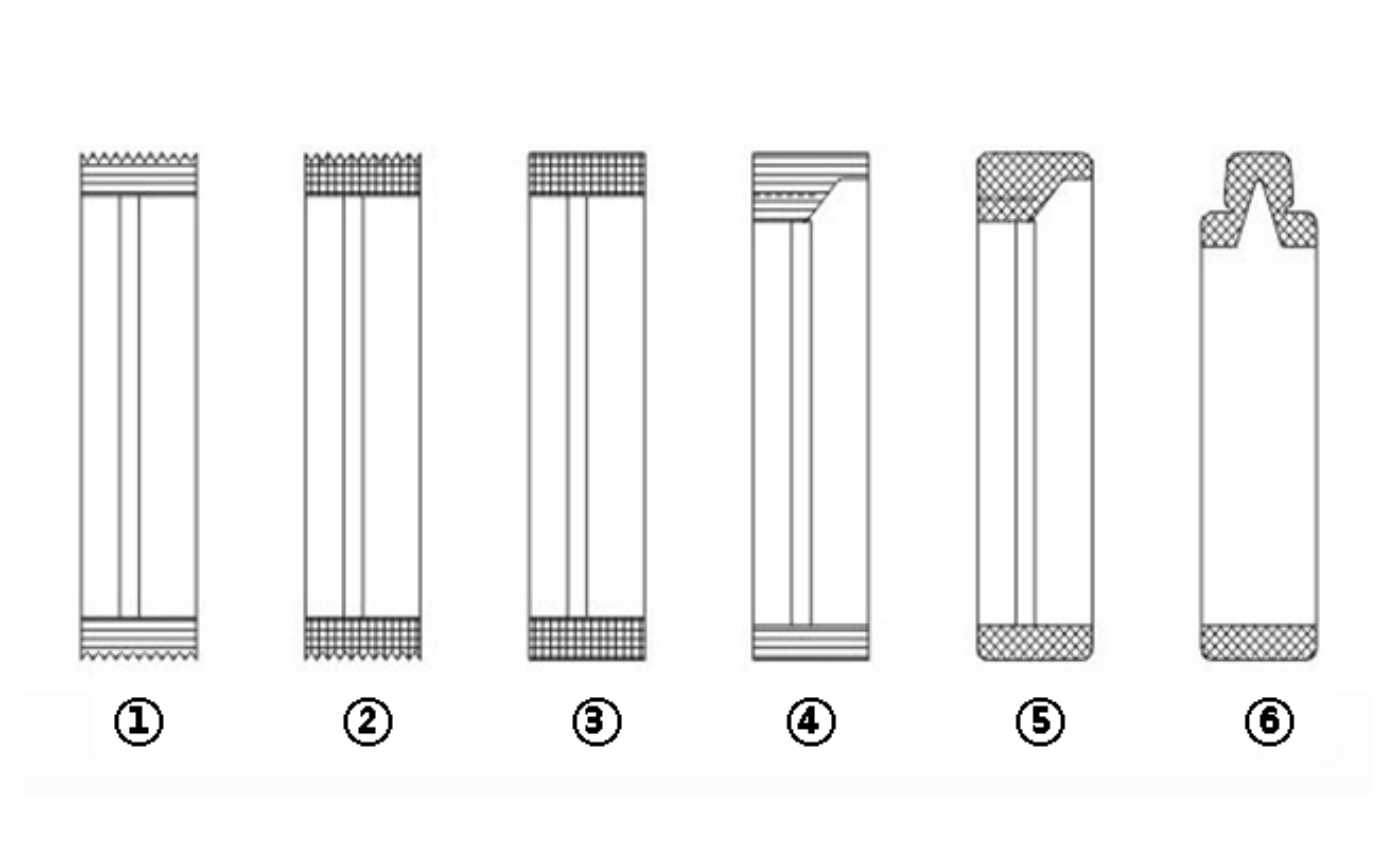

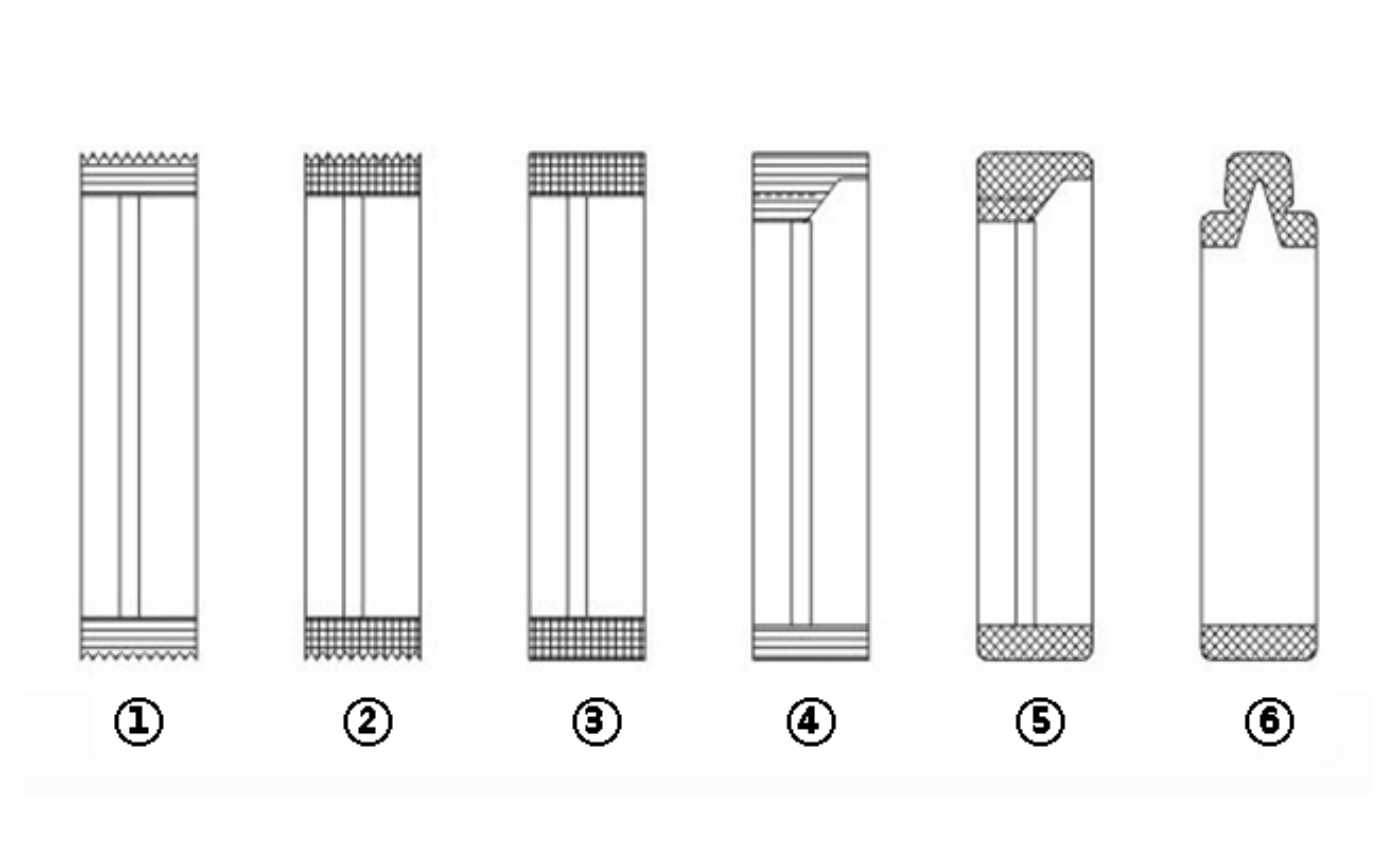

(7)Cutting type option: V shape cutting, straight cutting, round corner cutting, die-cut cutting type

Model | TT-480 | TT-720 | TT-960 |

Lanes are quant.

(depends on max. film width) | 4-6 lanes | 4-8 lanes | 4-12 lanes |

Capacity | 20-40 Bags/Min/Lane |

Film width( max.) | 480mm | 720mm | 960mm |

Bag size | L:45--120mm,W:35--60mm | L:45--120mm,W:35--90mm | L:45--120mm,W:35-120mm |

Air & Powder | 0.8mpa,0.8m3/min,2.8kw | 0.8mpa,0.8m3/min,4.1kw | 0.8mpa,0.8m3/min,5.5kw |

Dimension & weight | 950*1470*1750mm,350kg | 1153*1654*1750mm,450kg | 1415*1686*1750mm,600kg |

Cutting Type | 1. Flat Cutting, 2.Zigzag Cutting, 3. Continuous Cutting, 4. Customized Special Shap Cutting |

Optional device | Date Coder, Air-filling Device, Tear Notch Device |

Control System | PLC + Servo + Touch Screen |