The most common packing machine failures and solution

The most common packing machine failures and solution

Jammed or Stuck Products: This occurs when products get stuck in the machine and prevent it from functioning properly. To solve this issue, you can try clearing the jammed product and checking the machine's alignment and settings to prevent future jams.

Incorrectly Sealed Packages: This problem can be caused by improper sealing settings or worn-out sealing components. You can solve this by adjusting the settings, replacing worn-out components, or recalibrating the machine.

Inaccurate Fill Levels: This issue can be caused by incorrect settings, worn-out components, or poor product flow control. You can address this problem by adjusting the settings, replacing worn-out components, or improving product flow control.

Malfunctioning Sensors: This problem can occur when sensors fail to detect products or other components of the packaging process. To solve this, you can troubleshoot the

Machine Downtime: This occurs when the machine breaks down and is unable to operate. To solve this issue, you can perform routine maintenance, conduct regular inspections, and address any mechanical or electrical issues as soon as they arise.

Electrical Issues: This can include problems such as blown fuses, malfunctioning switches, or damaged electrical components. To solve this, you may need to repair or replace damaged components, or work with an electrician to address electrical issues.

Poor Quality Packages: This issue can be caused by incorrect settings, worn-out components, or faulty equipment. To solve this, you can adjust the settings, replace worn-out components, or invest in higher-quality equipment.

Environmental Factors: This can include issues such as temperature or humidity fluctuations, which can affect the performance of the packing machine. To solve this, you may need to adjust the settings or location of the machine, or invest in equipment that is designed to operate in specific environmental conditions.

Operator Error: This can include mistakes such as incorrect settings, improper operation, or failure to follow safety protocols. To solve this, it is important to provide proper training and supervision for operators, and to ensure that they follow established procedures and guidelines.

Mechanical Issues: This can include problems with gears, belts, motors, or other mechanical components. To solve this, you may need to repair or replace damaged components, or work with a technician to diagnose and address mechanical issues.

To prevent these issues from occurring in the first place, it is important to perform regular maintenance, conduct inspections, and train operators on proper usage and maintenance of the packing machine。

Of course, it's important to learn how to troubleshoot common problems yourself. However, if you find a reliable supplier who provides machines with good quality materials, there will be less chance of simple malfunctions or breakdowns, or the frequency of such occurrences will be very low. This will not delay your production, thereby improving your productivity and reducing your costs. A good supplier also needs to have an experienced technical team who can quickly help you solve problems and resume production when you encounter issues that you cannot solve on your own.

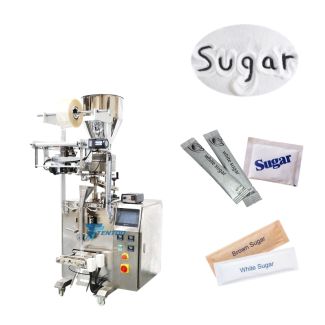

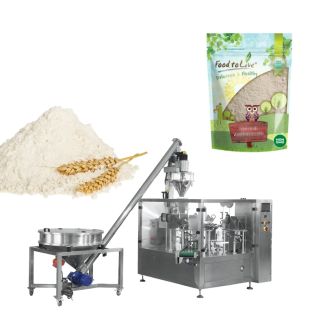

China TenToo 30 Over Years Experience In Sugar Machinery, Packaging,Top Manufacturer Of Packing Machine Export More Than 80 Countries,2 Years Warranty,Free Quote Free Video. Offer After-sale Service. Fast Shipping. 7*24 Online Service