How to package milk powder

Commonly milk powder is packaged by container or pouch.

For container, it mainly uses vacuum and nitrogen-filled packaging, and for pouch, it mainly uses inflatable packaging, Both of them can prevent moisture, oxidation, microbial growth and reproduction, and avoid ultraviolet radiation.

These two packaging methods have their own characteristics. The pouch size is small, easy to carry everywhere, and the packaging material is cheaper comparing to container, on the other side, container packing is with better sealing and protection.

Vacuum and nitrogen-filled packaging, it keeps container vacuum inside and controls the residual oxygen content below 3%. It isolates the material from contact with oxygen and prevents oxidation and deterioration. At the same time, it destroys the growth and reproduction environment of some aerobic microorganisms. Filling with nitrogen further ensures antioxidant effect and inhibition of microbial respiration.

Inflatable packaging is to fill the package with a certain proportion of ideal gas. The purpose is similar to vacuum and nitrogen-filled packaging. It is to destroy the environment which is suitable for the growth and reproduction of microorganisms and reduce the oxygen content inside the packaging.

Nitrogen is the most widely used inert gas in food industry today. It is odorless and tasteless, not easily soluble in water, and generally does not interact chemically with food. In order to prevent chemical reactions, more than 99.5% of the gas must be replaced, so gas replacement must be completed on high-performance packaging machine. For food packaging, nitrogen does not directly participate in the action of microorganisms. There are two main points: one is to fill the gas to ensure the intact form of the product; the other is to replace and inhibit the oxidation of the food itself and the respiration of microorganisms. Carbon dioxide can also achieve similar effects to nitrogen, but for the same film, the transmission ratio of the two is 1: (15-30). It can be seen that nitrogen is an ideal gas for food inflatable packaging.

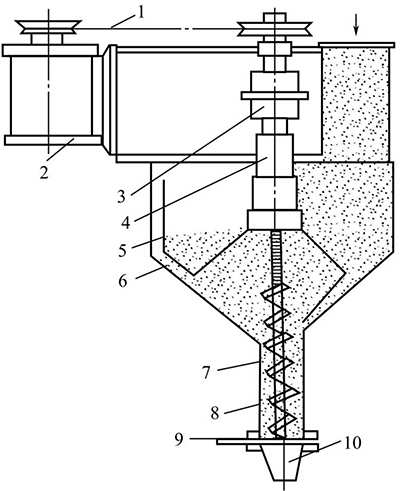

Main milk powder filling equipment - Screw filling machine

Since each pitch of the screw has a certain theoretical volume, the spiral groove is used as the cavity to measure materials. As long as the speed and number of revolutions of the screw are accurately controlled, the material can be measured. It should be noted that in order to fill the spiral groove with materials, the screw filling machine is generally installed vertically, so that the measurement is more accurate. Generally speaking, the accuracy can reach 1%.

Main milk powder packaging equipment

Stand up pouch packing machine

Tentoopack as an experienced packaging solution expert, providing complete solutions for milk powder packaging. Please feel free to contact us if you are interested in these machine.