What are the best gummy packaging machine?

What is the best gummy packaging machine on the market?

With the progress of society and the increasing demand for industrialization, packaging machines have become more and more popular. After our research, we found that many customers are concerned about issues related to packaging machines and seek advice on Google. The most commonly searched question on Google related to soft candy packaging machines is "What are the best soft candy packaging machines on the market?" In this article, we will explore the answer to this question and provide insights on what to look for when choosing a soft candy packaging machine for your business. This comprehensive guide will help you make an informed decision and ensure that your production line runs smoothly and efficiently.

Introduction pack bag

1. Gummy packaging machines are crucial in the candy manufacturing industry. These machines help to efficiently package soft candies into various packaging formats, such as pouches, sachets, and bags. With the growing demand for soft candies, manufacturers need to invest in the right packaging machine to maintain high production standards and meet consumer expectations.

Factors to Consider when Choosing a Soft Candy Packaging Machine

Package size

1. Type of packaging format: Different soft candy packaging machines are designed to handle different packaging formats. It is essential to choose a machine that can handle your desired packaging format, whether it be pouches, sachets, or bags.

Production capacity

The production capacity of a soft candy packaging machine refers to the number of candies that it can package in a given time frame. It is essential to choose a machine that can meet your production needs without compromising the quality of the packaging.

machine Level of automation

Some soft candy packaging machines are fully automated, while others require manual intervention. Fully automated machines are more efficient and can help to reduce labor costs, but they are also more expensive. Consider your budget and production requirements when deciding on the level of automation for your machine.

Level of customization

Some soft candy packaging machines are designed to handle a specific type of candy, while others can handle a wide range of candies. It is essential to choose a machine that can be customized to meet your specific packaging needs.

machine Reliability

A reliable soft candy packaging machine is essential to ensure that your production line runs smoothly without any downtime. It is essential to choose a machine that has a good track record of reliability and is made from high-quality materials.

supplier After-sales support

Soft candy packaging machines are complex machines that require regular maintenance and repair. It is essential to choose a manufacturer that provides excellent after-sales support to ensure that your machine operates at peak efficiency.

Own budget

CBD candy gummy packaging machines can be expensive, and it is essential to choose a machine that provides value for money. It is also important to consider the maintenance and repair costs of the machine.

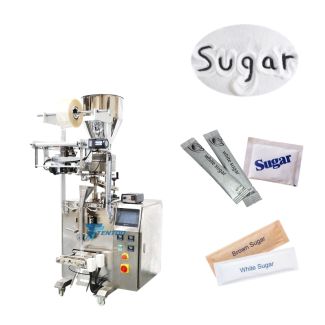

Several common gummy packaging machines

Machine Features:

1. The machine features an imported PLC full computer control system, and color touch screen, and is easy to operate, intuitive, and efficient.

2. Equipped with an imported servo film transport system and imported color code sensor, the machine provides accurate positioning, excellent overall performance, and beautiful packaging.

3. The machine comes with a variety of automatic alarm protection functions to minimize loss.

4. Flat cutting, pattern cutting, and linking cutting can be realized by changing the tools, and the machine provides easy operation with smooth bags.

5. The bag-making equipment can be changed according to the specific requirements of customers and products.

6. The machine features an optional English or other language screen display, making it easy and simple to operate. Both packaging speed and bag length can be set with one click.

All machines have CE certification and ROSH certificate.

gummy packaging machine parameter

| Model | TT-320 |

| Film width | Max.320mm |

| Bag length | 30-200mm |

| Bag width | 30-150 mm |

| Packing grams | 10-200ML |

| Power | 220V/380V/50/60 HZ |

| Packing speed | 30-70bag/min |

| Cutting type | Straight cutting, Zig zag cutting, Round cutting, Special Cutting |

| Powder | 2.0KW |

| Machine Weight | 400KG |

| Dimensions (mm) | 1200*1050*1650 |

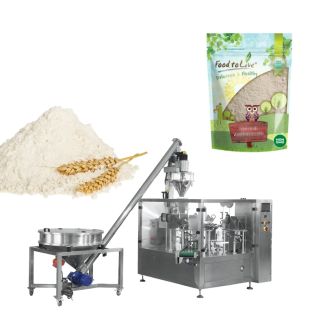

Main Features:

1. Full-automatic weigh-form-fill-seal type machine, efficient and simple to use.

2. Equipped with famous brand electric and pneumatic components, ensuring stability and a long life cycle.

3. Utilizes superior mechanical components to reduce wear and tear.

4. Easy to install the film and automatically corrects the excursion of the film.

5. Features an advanced operating system that is easy to use and reprogrammable. When used with the Uboray high-quality machine, it makes your packing work easy and efficient.

gummy bear packaging machine parameter

Model | TT-420 | TT-520 | TT-620 | TT-720 |

Film width | Max.420mm | Max.520mm | Max.620mm | Max.720mm |

Bag length | 80-300mm | 80-400mm | 80-500mm | 80-600mm |

Bag width | 50-200 mm | 70-250 mm | 60-300 mm | 200-350 mm |

Packing grams | 50-1500ML | 50-2500ML | 50-4000ML | 50-5000ML |

Power | 220V/380V/50/60 HZ | |||

Packing speed | 30-70bag/min | |||

Cutting type | Straight cutting, Zig zag cutting, Round cutting, Special Cutting | |||

Powder | 2.0KW | 2.2KW | 3.0KW | 4.0KW |

Machine Weight | 400KG | 480KG | 550KG | 690KG |

Dimensions (mm) | 1200*1500*1700 | 1500*1600*1800 | 1600*1700*1800 | 1600*1700*1800 |

Automatic Premade Gummy Packaging Machine

Main Features:

1. Z-shaped bucket elevator/incline conveyor raises material to the multi-weigher, which controls the start and stop of the hoister.

2. Multihead weigher with 10/14/20 heads for weighing the target weight.

3. Platform to support the multi-weigher.

4. Rotary packing machine for packing pre-made pouches, including bag retrieval, date printing, zipper bag opening, filling from the multi-head weigher, optional positioning, hot sealing, and cold sealing.

gummy bear packaging machine parameter

Model | TT-200/TT250 | |||

Pouch Size | W: 80-350mm/L:100-300mm | |||

Filling range | 10-3000g | |||

Capacity | 40-60bag/min(speed is determined by the product filling quantity) | |||

Dosing Systems | Multi-head combination scale, Linear scale, Volumetric cup, Auger filler, Piston filler, etc. | |||

Power | 220V/380V/50/60 HZ(or customize according to specific demands) | |||

Average precision | ≤ ±1% | |||

Cutting type | Straight cutting, Zig zag cutting, Round cutting, Special Cutting | |||

Powder | 2.5KW-3.5kw | |||

Machine Weight | 1850KG | |||

Dimensions (mm) | 2200x1850x1700mm | |||

Main standard parts | 1. Code printer 2. PLC control system 3.Bag opening device 4. Vibration device 5.Cylinder 6. Electromagnetic valve 7. Temperature controller 8.Vacuum pump 9. Inverter 10. Output system | |||

Automatic Gummy/Candy Filling Machine

Machine Features:

1. The entire machine is made of stainless steel, making it suitable for GMP certification, food hygiene certification, and anti-corrosion chemical products.

2. The touch screen man-machine interface ensures stable operation. The weight of the package can be adjusted steplessly at any time, and the working status can be changed easily.

3. Filling adopts a servo motor, providing accurate positioning, high precision, high speed, large torque, long life, and good stability. The speed can be set according to your needs.

4. The stirring mechanism uses a Taiwan geared motor, which is low noise, has a long life, and requires no maintenance.

5. The feedback proportion tracking system overcomes the disadvantages of weight changes due to changes in the proportion of materials.

6. The fully sealed air-resistance glass stainless steel side-opening compound material hopper provides clear visibility of materials and dust without leaking. The outlet is equipped with a suction device to protect the workshop environment.

gummy filling machine parameter

Model | TTP-020 | |||

Filling Weight | 10-5000g(customizable) | |||

Bottle diameter | Φ30-Φ140mm(customizable) | |||

Bottle height | 50mm-200mm(customizable) | |||

Power | 220V/380V/50/60 HZ | |||

Packing speed | 30-55 bottles/min | |||

Measurement accuracy | ≤500g,≤±1%;>500g,≤±0.5% (Varies due to the characteristics of the material) | |||

Powder | 3.5KW | |||

Machine Weight | 750KG | |||

Dimensions (mm) | 4400*1.2*1800(L*W*H mm) | |||

Automatic Flow Candy Packing Machine

Main Features:

1. Dual frequency conversion control allows for bag length to be set and cut in one step, saving time and film.

2. The interface features easy and quick settings and operations.

3. Self-failure diagnosis provides a clear failure display.

4. High sensitivity photoelectric eye color tracing and numerical input of cutting sealing position for extra accuracy.

5. Temperature-independent PID control is more suitable for packaging different materials.

6. Positioned stop function prevents sticking the knife or wasting film.

7. Simple driving system ensures reliable working and convenient maintenance.

All control is realized through software, making it easy for function adjusting and technical upgrades.

Flow gummy packaging machine parameter

Model | TT-250 | TT-350 | TT-450 | TT-600 |

Film width | Max.250mm | Max.350mm | Max.450mm | Max.600mm |

Bag length | 65-280mm | 65-330mm | 150-450mm | 160-500mm |

Bag width | 30-110 mm | 50-160 mm | 50-180 mm | 100-280 mm |

Product Height | Max.55mm | Max.60mm | Max.75mm | Max.110mm |

Power | 220V/380V/50/60 HZ | |||

Packing speed | 30-230bag/min | |||

Powder | 2.0KW | 2.2KW | 3.0KW | 4.0KW |

Machine Weight | 480KG | 560KG | 650KG | 720KG |

Dimensions (mm) | 4030*770*1420 | 4030*770*1420 | 4030*970*1500 | 4030*1070*1500 |

Optional Devices | 1. Lateral feed device, 2.Straight feed device, 3.Belt material conveyor, 4. End sealing auxiliary conveyor, 5. Auxiliary material feeding device, 6. Material cuts prevent the device,7. The perforating device, 8.Angle folding device, 9. Date Printer, 10.Labeling machine | |||

Foshan TENTOO Packing Machine Candy Gummy Packaging Machine: This machine is known for its high production capacity and fully automated operation. It can handle a wide range of packaging formats and is easily customizable to meet your specific needs.

Foshan TenToo Top Manufacturer Of Packing Machines Export More Than 40 Countries Experienced Sugar Packing Machine Expert Offer You Optimum Solution

Free Quote Now! Free Video. Offer After-sale Service. Fast Shipping. 7*24 Online Service

Free design scheme Machine quality assurance!2 Years Warranty

If you have any, you can leave a message on our official website, we will reply to you within 8 hours free of charge for you to answer

Conclusion

In conclusion, when choosing a soft candy packaging machine, it is essential to consider several factors, including the type of packaging format, production capacity, level of automation, level of customization, reliability, after-sales support, and cost. By considering these factors, you can choose the best soft candy packaging machine for your business and ensure that your production line runs smoothly and efficiently. Investing in the right packaging machine will not only help you meet consumer expectations but also increase your brand's visibility on platforms like Google, ultimately leading to increased sales and business growth.