How do we maintain automatic packaging machines

How do we maintain automatic packaging machines

- According to market research agencies, the globa full automaticl packaging machinery market size increased from around $14 billion in 2016 to approximately $18 billion in 2020.

- It is expected that by 2025, the global packaging machinery market size will further increase, reaching over $20 billion.as China packing machinery supplier,according to Chinese customs data, China's packaging machinery exports reached about $12 billion in 2019 and grew to about $13 billion in 2020

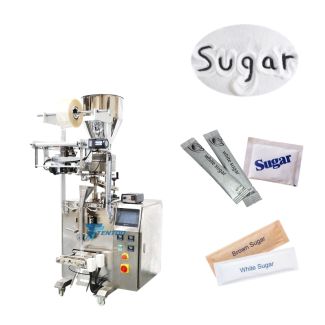

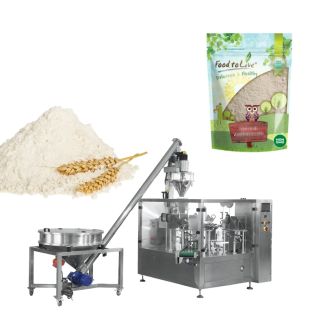

- Major types of packaging machinery include automatic powder filling machines, sealing machines, labeling machines, packaging robots, among others, with the packaging robot market growing rapidly and expected to maintain high growth in the coming years.

Overall, packaging machinery has evolved from simple manual equipment to automation, digitization, and intelligence. The market size continues to expand, and the technological level continues to improve, providing strong support for the development of the packaging industry.

As more and more people are using packaging machinery, many individuals lack the knowledge of maintenance and repair. Today, I will share with you how to properly maintain machinery.

1. Lubrication: regularly add engine oil to the meshing parts of each gear, the oil filling hole of the bearing with the seat, and each moving part, once per shift.

2. The reducer is strictly prohibited from operating without oil. After the first 300 hours of operation, clean the inside and replace it with new oil. Change the oil every 2500 hours after that. Especially the premade bag packaging machine

3. When adding lubricating oil, please be careful not to drip oil on the transmission belt to prevent slipping and loss of rotation or premature aging and damage to the belt.

4. Maintenance: Check the screws in all parts regularly to ensure they are not loose.

5. The electrical parts should be waterproof, moisture-proof, anti-corrosive, and rodent-proof, and ensure that the inside of the electric control box and the wiring terminals are clean to prevent electrical faults.

6. When stopping the machine, the two heat-sealing bodies should be in an open position to prevent the packaging material from being scalded.

7. Cleaning: The metering part should be cleaned promptly after shutdown. For packaged materials with high sugar content such as granules, the turntable and unloading door should be cleaned every shift.

8. Clean the heat sealer body frequently to ensure clear sealing lines of the finished packaging bag.

9. Scattered materials should be cleaned up in time to keep the machine parts clean to extend the service life.

10. Clean the light-emitting head of the photoelectric switch (electric eye) frequently to ensure its reliable operation.

11. Clean the dust in the electric control box frequently to prevent electrical faults such as short circuits or poor contact.

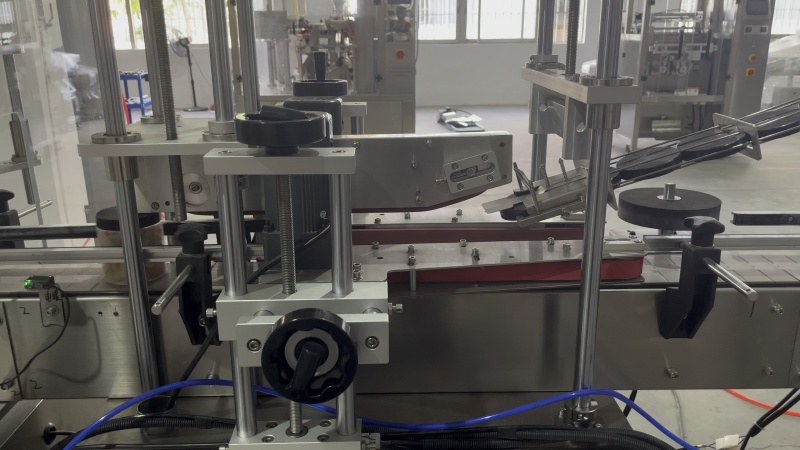

I have to mention one point here,As a customer of our Tentu Packaging machinery company,

We provide a maintenance manual,There are also basic problems how to simple maintenance,

If you can't solve it, we have 30 years of experience teachers, one-on-one guidance, and even we can send teachers to your country to repair and help you

The picture shows our engineers helping customers to update the packaging machinery program system and going to the customer's country