Exploring the World of Infant Formula Packaging Machines

Exploring the World of Infant Formula Packaging Machines

In the realm of product packaging, specialized machines have revolutionized various industry verticals, such as Industrial agriculture People's Daily life

A unique and significant sector that has immensely benefited from this technological advancement is the infant formula industry. The infant formula, also known as baby milk powder, requires high standards of precision, hygiene, and efficiency during its packaging process, which is impeccably catered to by dedicated milk powder packaging machines.

Understanding Milk Powder Packaging Machines

Everyone knows that milk powder babies eat, so everything about milk powder is very strict, and people also attach great importance to it, Milk powder packaging machines play a critical role in delivering the perfect balance of safety, quality, and efficiency in the infant formula industry. These machines ensure that every package is filled with the precise quantity of product, and sealed appropriately to maintain freshness and safeguard against contaminants. They also provide essential information about the product, such as nutritional facts, expiration dates, and instructions for use.

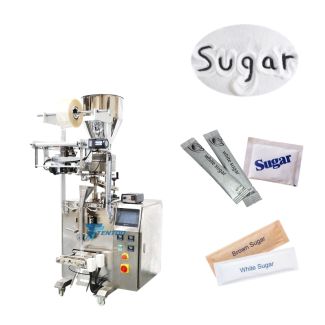

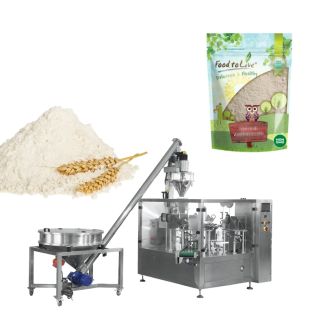

Milk powder packaging machines are typically equipped with technologies such as volumetric fillers or auger fillers for precise product measurement, coupled with a sealing system, which could be heat seal, ultrasonic seal, or even vacuum seal. Additionally, they often include coding and labeling systems for applying batch numbers, manufacturing dates, expiry dates, and barcodes.If you want to know more about milk powder packaging machines, you can browse TT200 machine

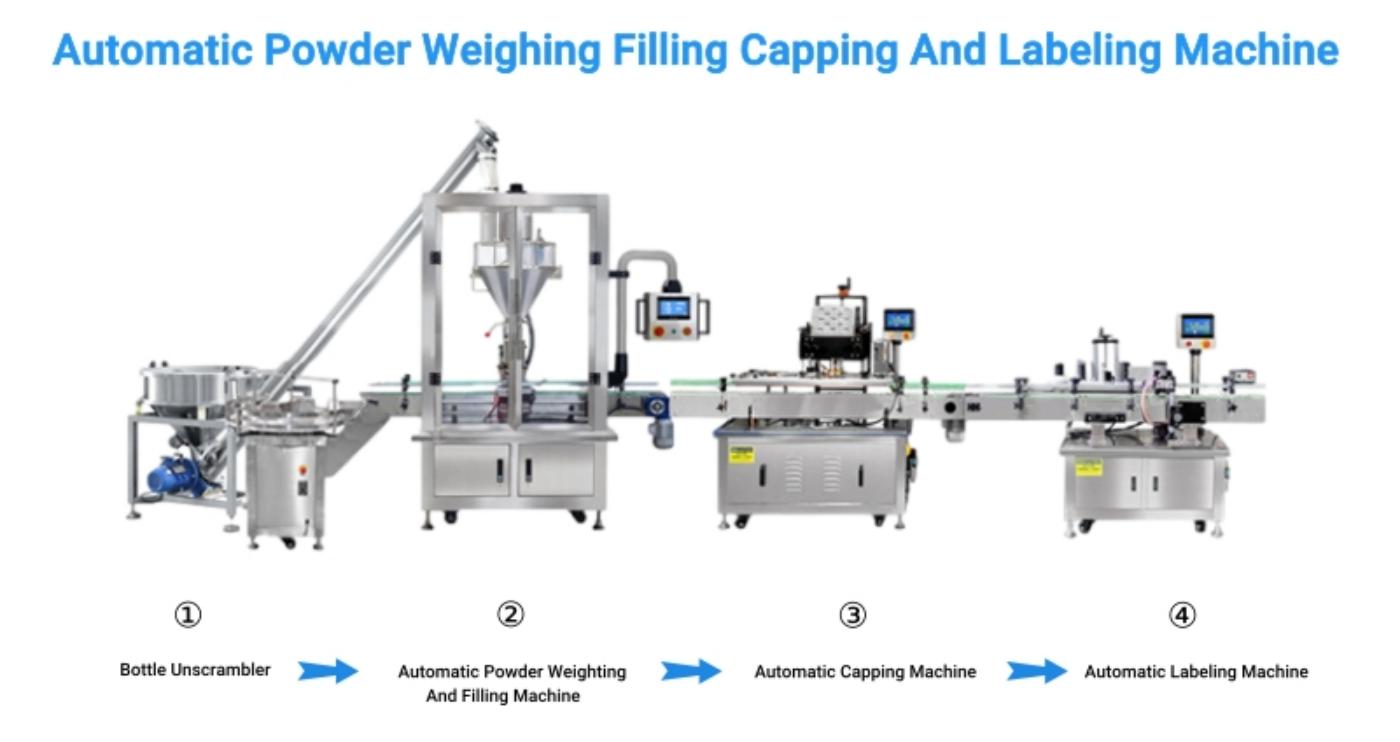

The following is a picture of the popular milk powder packaging machine sold on the market

Key Aspects of Milk Powder Packaging Machines

The design and operation of milk powder packaging machines require high consideration for safety and hygiene, given the sensitive nature of their intended consumers - infants. The machines are usually made of food-grade stainless steel, preventing any risk of contamination. Furthermore, they are designed to be easy to clean and sanitize.

The machines also prioritize efficiency and precision. High-speed packaging ensures that the supply meets demand while minimizing production costs. On the other hand, precise filling mechanisms ensure each package contains the exact amount of product, ensuring consistency and trustworthiness.

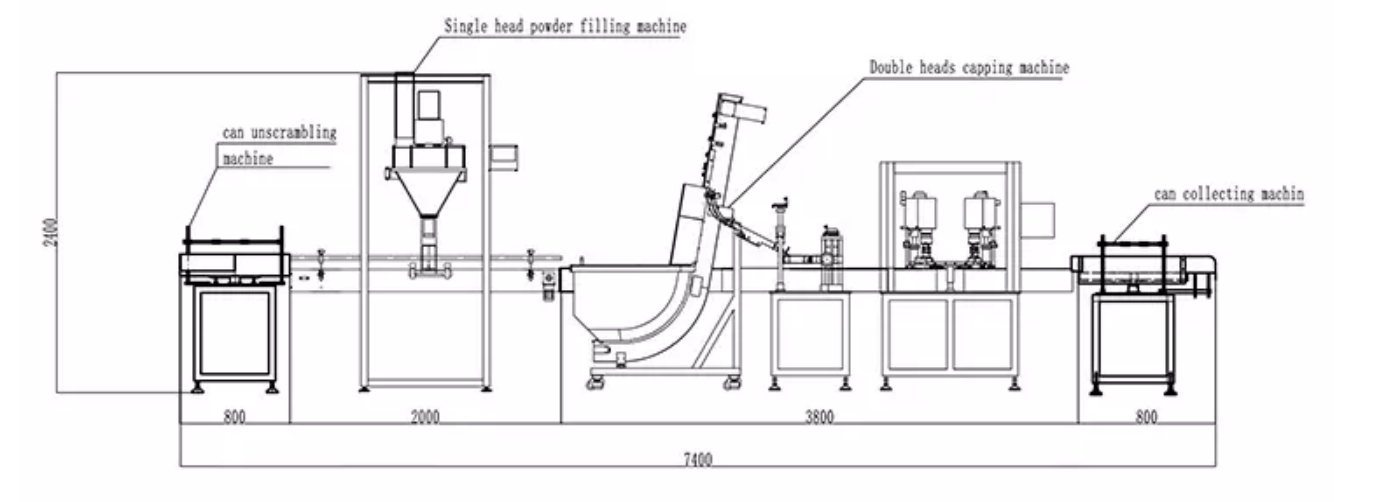

milk powder filling machine schematic diagram