Leave your email and will receive a $500 coupon now!

Detergent Packing Machine Description

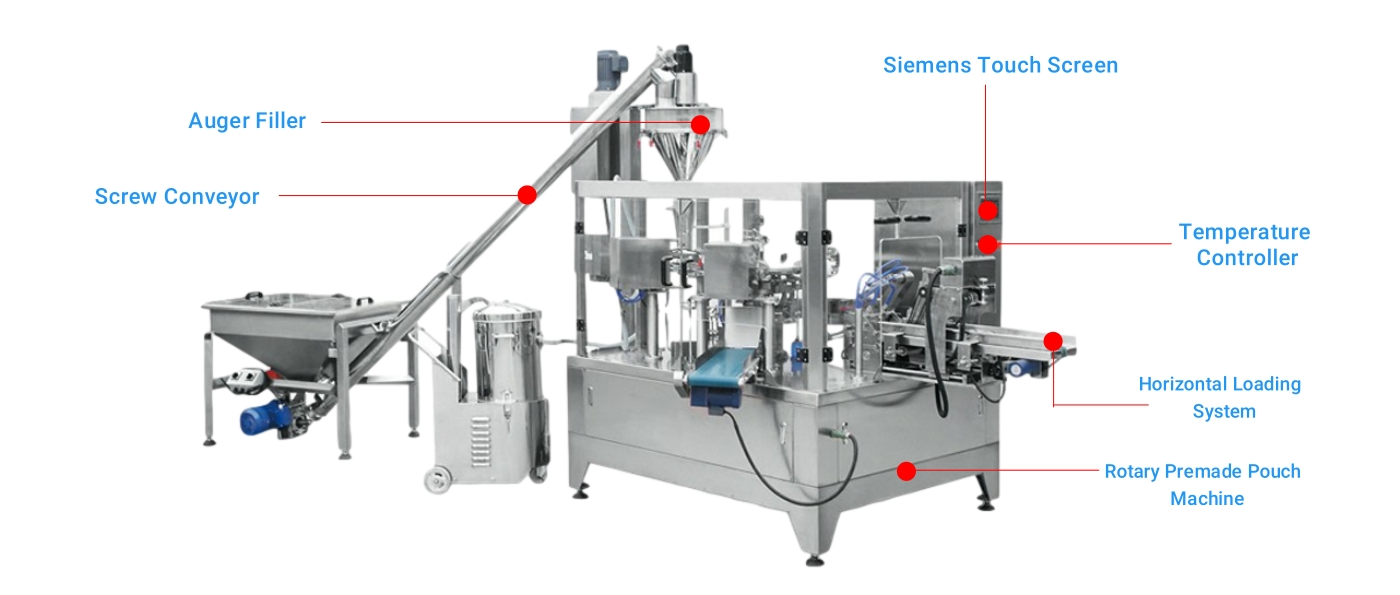

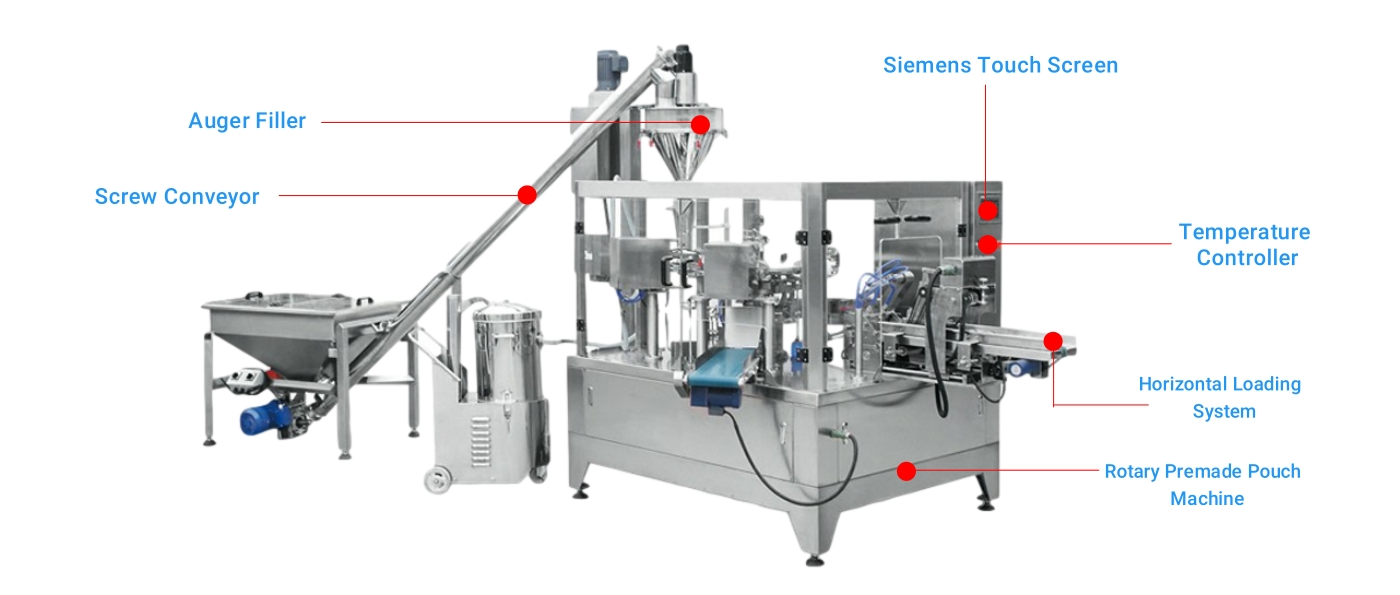

Washing Powder Packing Machine Structure Features

1. It uses stainless steel 304 shell for the food grade required.

2. Automatic detection. No pouch or pouch is not opened completely, no filling, no sealing.

3. Horizontal Infeed conveyor suits for bags with zipper, max. put 300pcs each time.

4. Zipper Openner System: Servo motor (Yaskawa / Japan) controlled.

5. Independent temperature control system (Omron/Japan).

6. PLC adjusts bag width clamping: Only needs 2mins by auto PLC to adjust different bag width sizes.

7. Automatic lubrication system: PLC controls the lubrication time, and automatically lubricates the machine parts instead of manually.

8. It includes ribbon type date code: 3 lines * 17 characters.

9. Guarding: Glass Door Alarm / Air Pressure Abnormal

10. This premade bag detergent packing machine Internal grooved cam design: The technology with high precision, suits for max. packing

speed: 50 cycles/min with stable running

11. Use a free oil vacuum pump, to avoid polluting the environment in the production.

| SPECIFICATIONS FOR PACKAGING MACHINE |

| Packing specification | Model | TT-200 | TT-250 |

| Bag width | 70-200 | 100-200 |

| Filling range | 10-1000g | 20-2500g |

| Main performance parameters | Packing speed | 40-60bag/min(speed is determined by the product filling quantity) |

| Average precision | ≤ ±1% |

| Total power | 4.5kw | 5kw |

| Dimensions | 1900mm X 1570mm X 1700mm(L*W*H) |

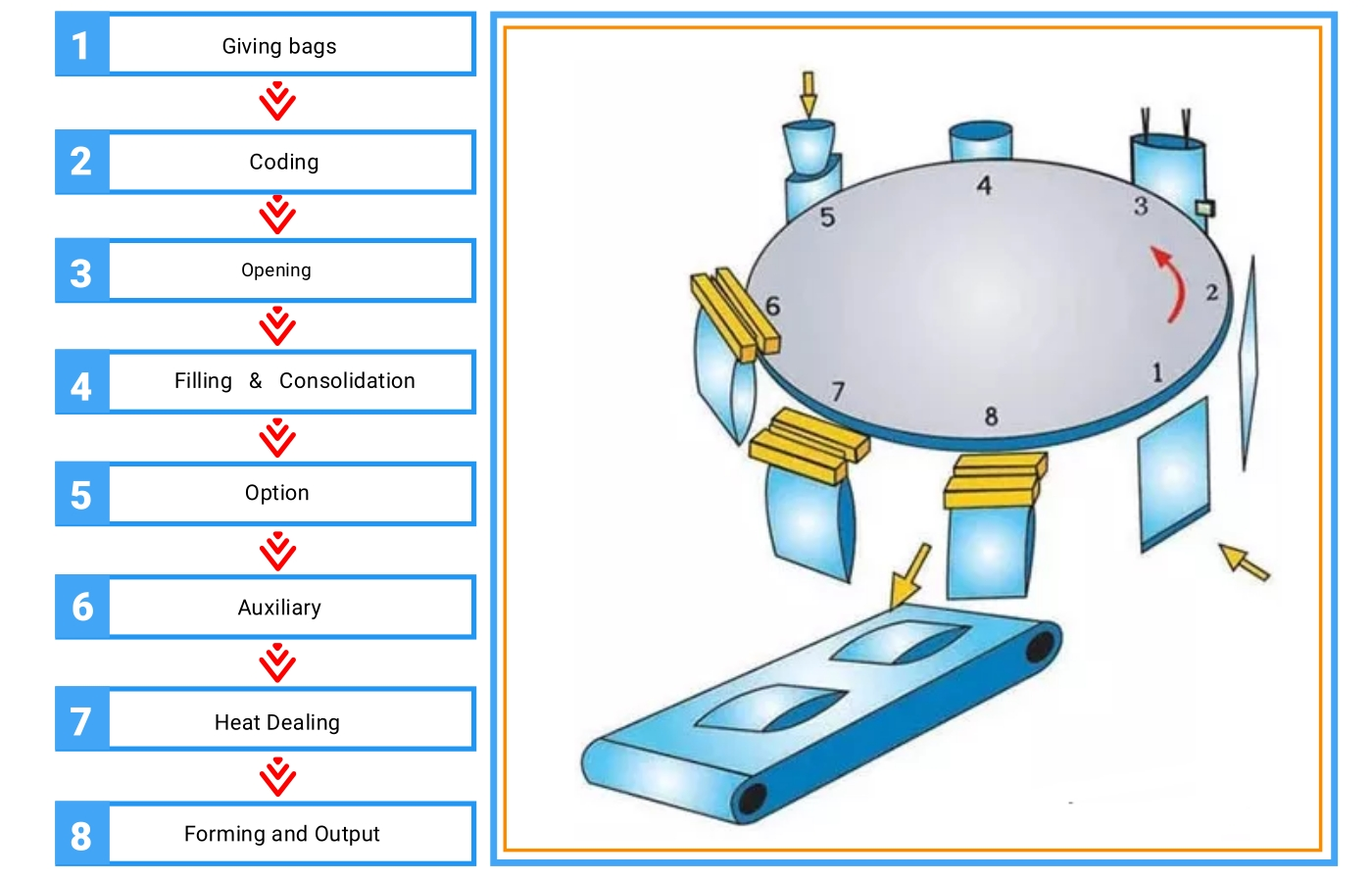

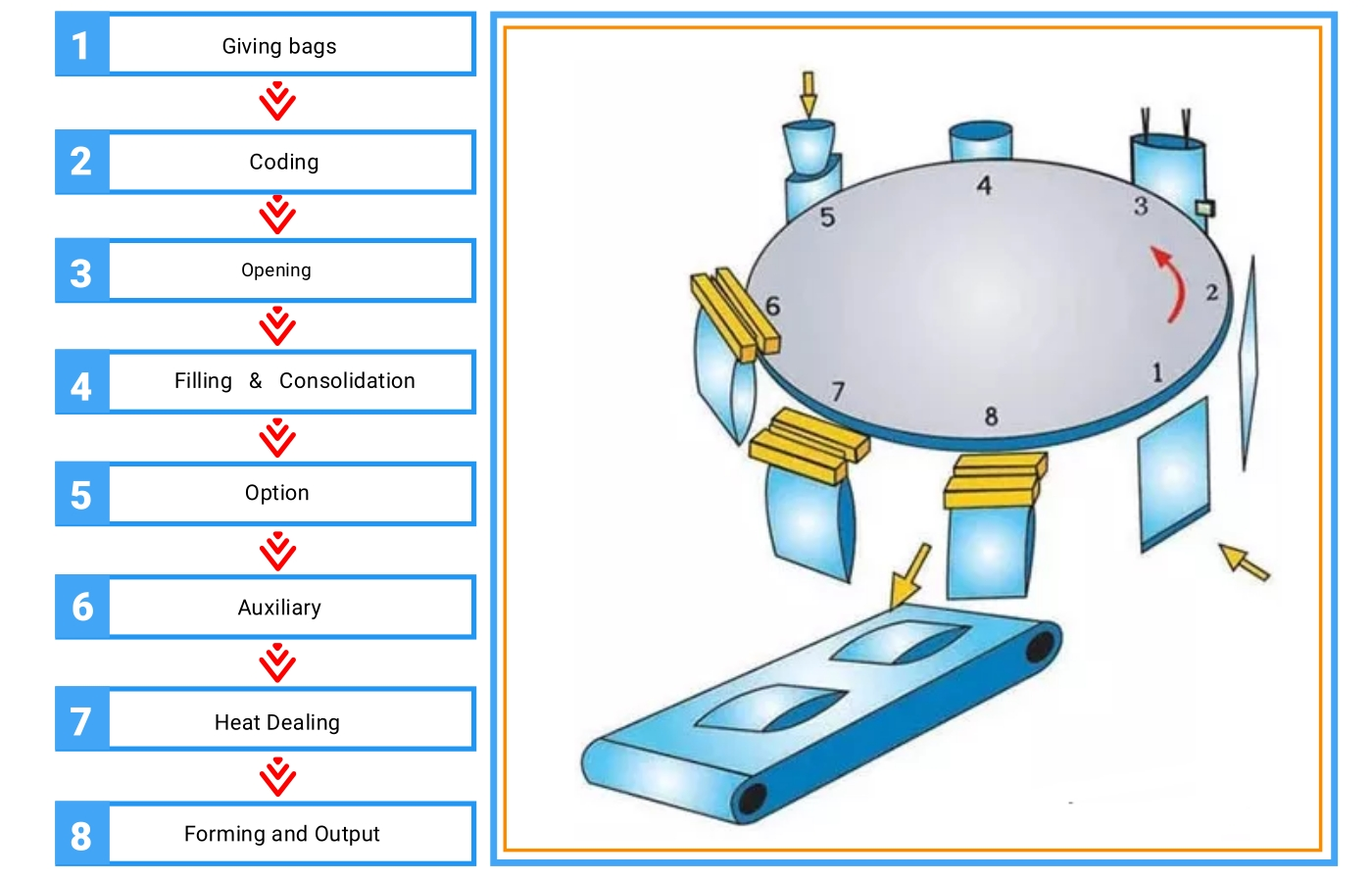

| Working flow | giving bag→coding →opening →filling 1 →filling 2→ auxiliary→ exhaust→heat sealing→ .forming and output product |

| 1. Code printer | 2. PLC control system | 3. Bag-opening device | 4. Vibration device |

| 5. Cylinder | 6. Electromagnetic valve | 7. Temperature controller | 8. Vacuum pump |

| 9. Inverter |

| 10. Output system |

|

Detergent Powder Packing Display

Washing Powder Packing Machine Detail

Workshop Display

Detergent Pouch Packing Machine Certificate

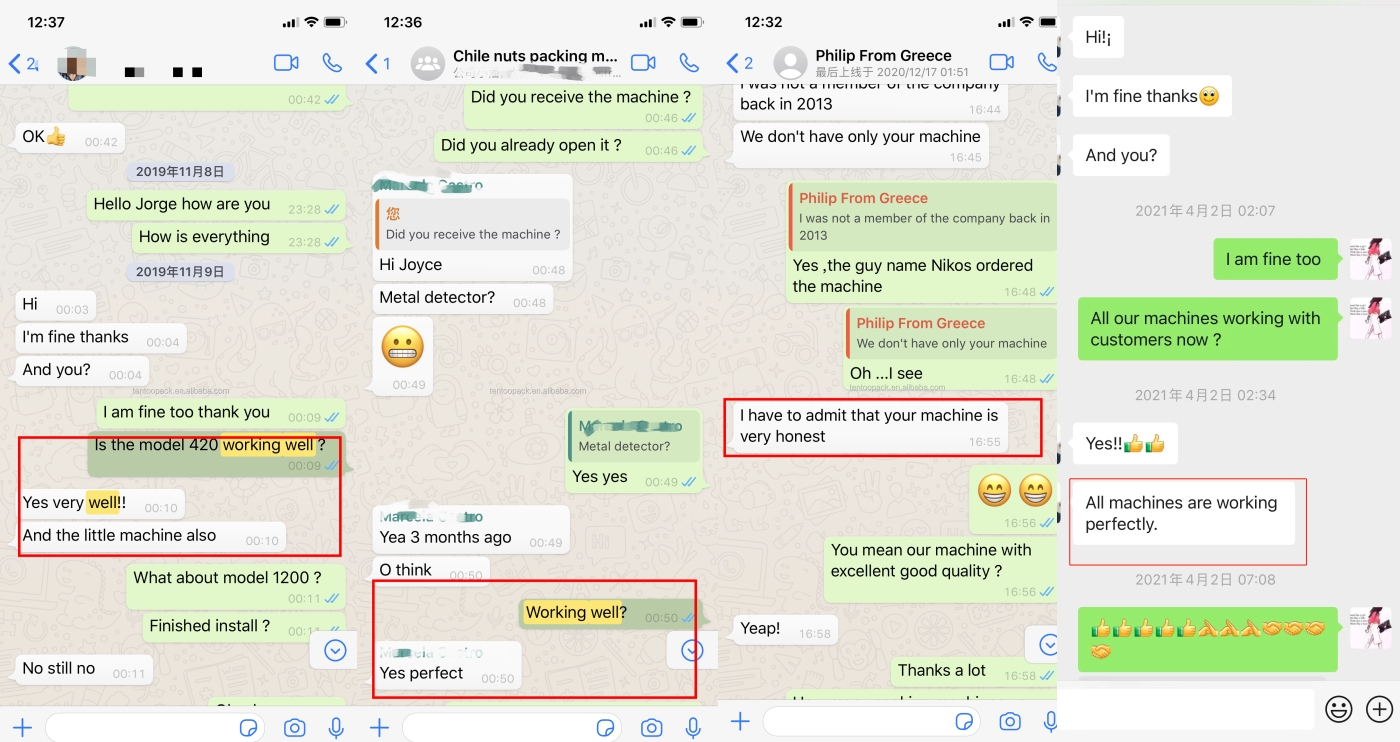

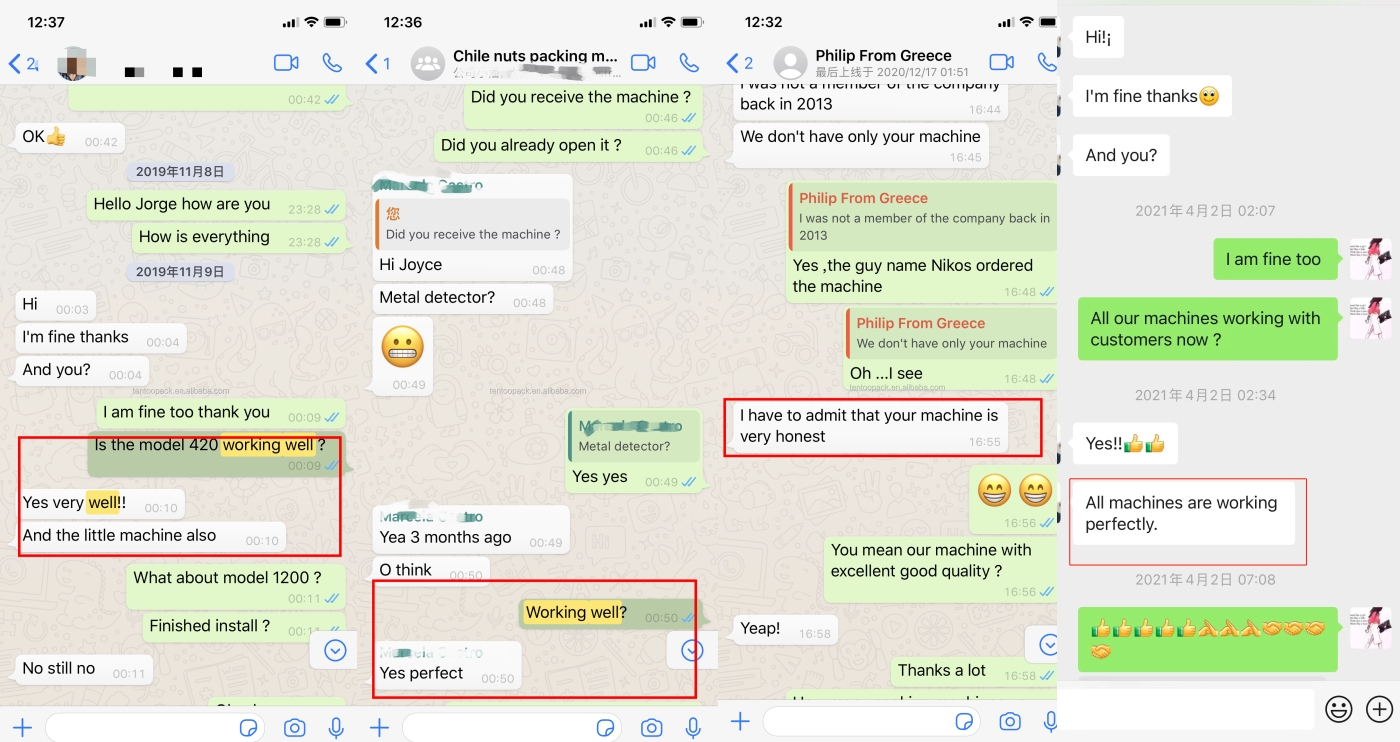

Customer Feedback

After-Sales Technician And Customer Communication

After-sales Services

1. Manuls / Videos of machine installation, adjusting, setting, maintenance are available for you.

2. If any problems happend and you can not find out the solutions, Telecom or Online face to face communication available 24hours.

3. Tentoo engineers & technician are available send to your countries for services if you agree pay the expenditure.

4. The machine will have One year guaranty for machine, two years guaranty for electrical part. During the warranty year if any of the parts broken not by man-made. We will free charge to replace the new one to you. The warranty will begin after the machine send out we received the B/L.

5. TENTOO has an independent team for after-sale service. Any emergency please call the saleman or our after-sale's manager.