Send an inquiry and receive a $500 coupon

Overview

Meets FDA requirements and follows cGMP guidelines

rotary filling design

High-accuracy multi-head filling station

Diving nozzles for optimized filling cycle

Positive pick and place plugging station

Positive pick and place cap placement and/or pre-tightening station

Independent final cap torquing/crimping station with torque control

Compatible with 5 types of bottles, , no need to change accessories, various round bottles, square bottles, octagonal/ special-shaped bottles, hexagon bottles, etc;

Liquid detergent Filling Machine Parameter

| Automatic Liquid Filling Capping And Labeling Machine |

| Model | TTP-020 |

| Filling Weight | 10-1000ml(customizable) |

| Bottle diameter | Φ30-Φ140mm(customizable) |

| Bottle height | 40mm-320mm (customizable) |

| Production speed | 10-55 Bottle/min |

| Measurement accuracy | ≤500ml,≤±1%;>500ml,≤±0.5% (Varies due to the characteristics of the material) |

| Power | 4.5kw |

| Working Pressure | 0.6-0.8MPa |

| Control system | PLC |

| Filling head | four heads/ten heads can be customized |

| Weight | 1200kg |

Dish Wash Liquid Filling Machine Application

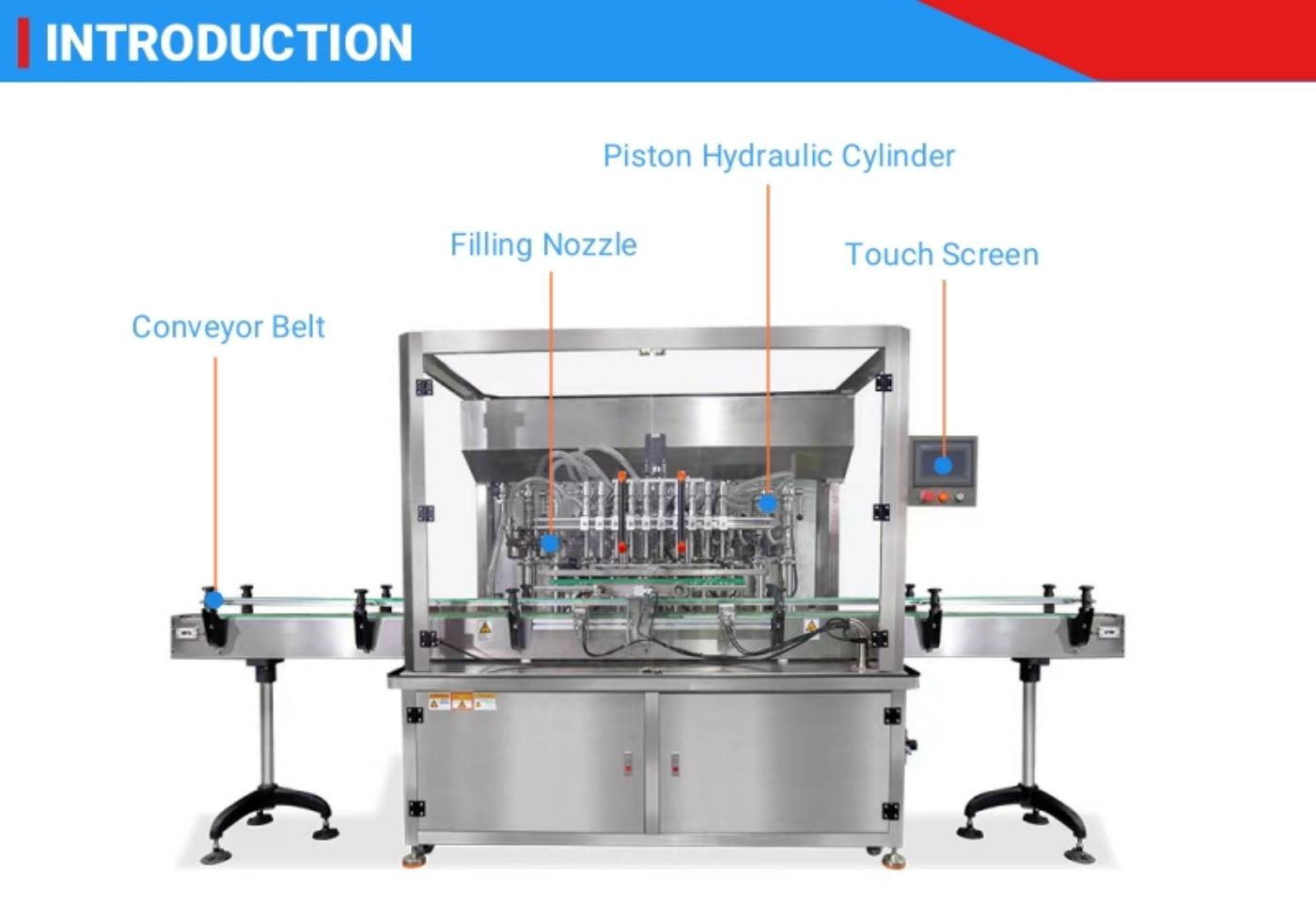

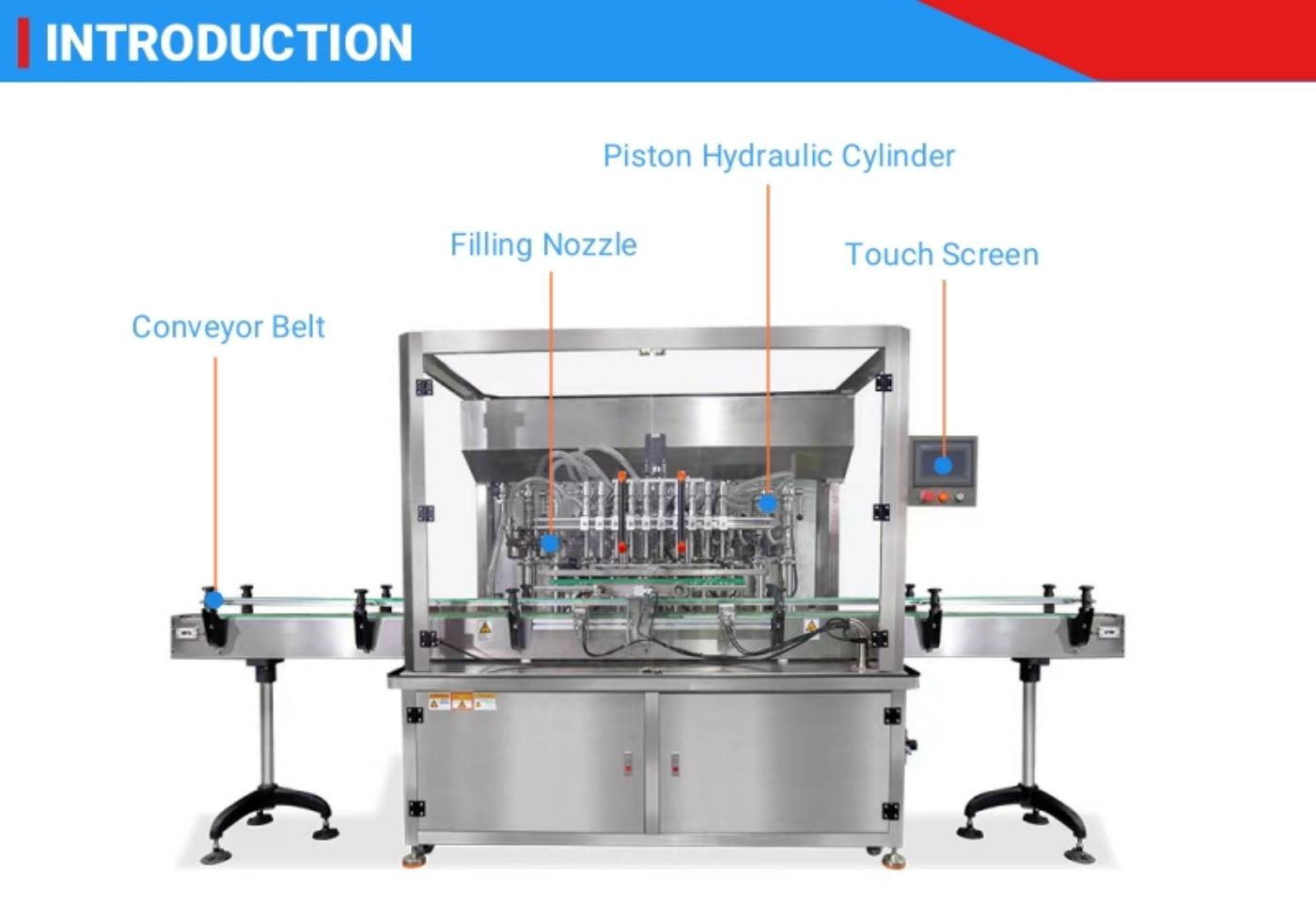

This detergent filling machine is suitable for filling viscous, inviscid, and corrosive liquids. It's widely applied in plant oil, chemical liquid, and the daily chemical industry. It adopts linear type filling,electromechanical&instrucmental integration controlling. It's simple and rapid for changing the varieties with unique designs and superior capability. Its appearance accords with the international machinery concept.

Germany SIEMENS PLC and touch screen control make it an intelligent protection function. A vacuum anti-dropping device ensures no leaking situation in production. Electronic adjusting for volume system, frequency control, and photoelectric detecting system(Germany TURCK brand) are applied in this machine.